Rajoo

Instagram

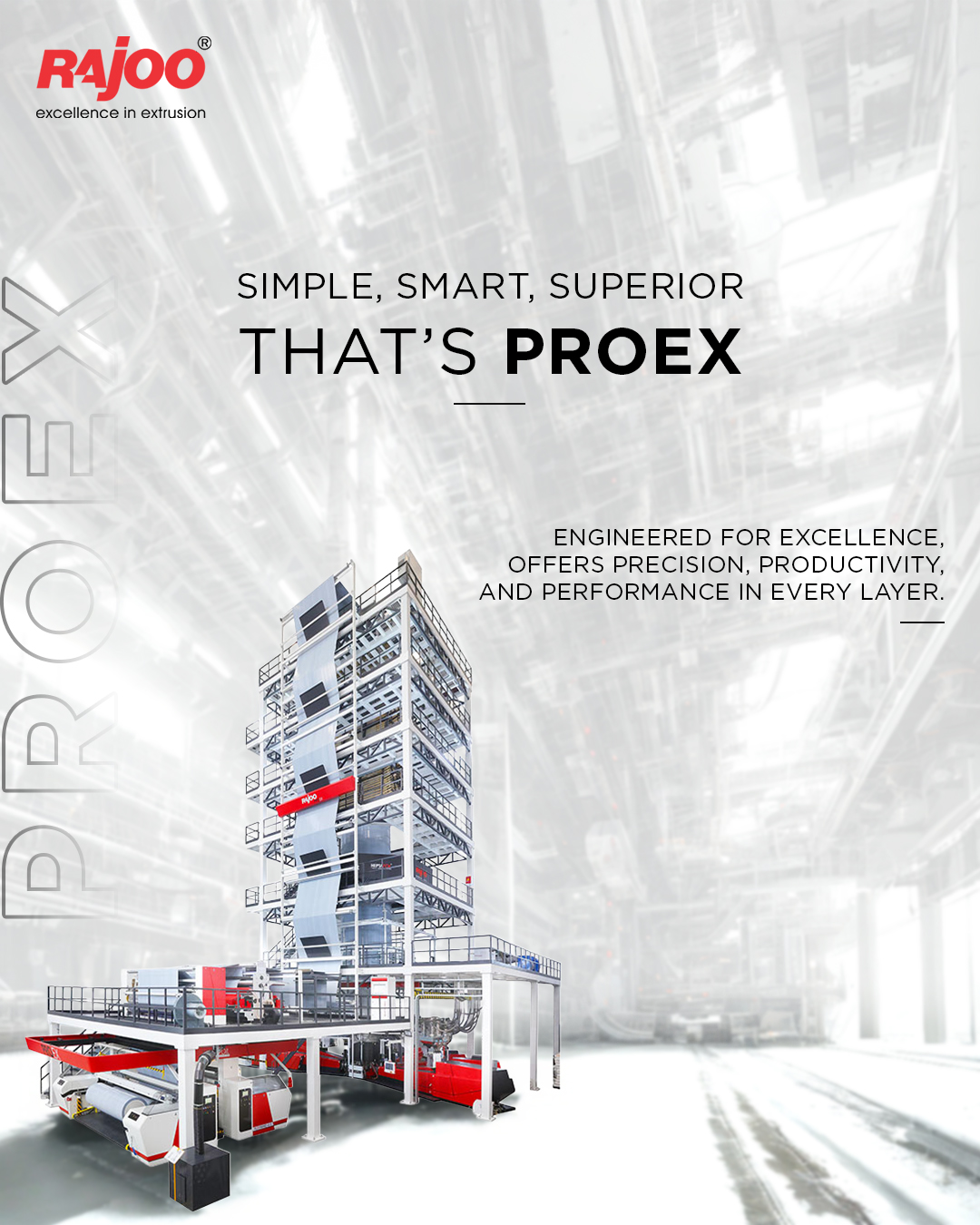

Whether you're processing HDPE (High-Density Polyethylene), LDPE(Low Density Polyethylene), or LLDPE(Linear Low-Density Polyethylene), PROEX delivers consistent film quality with superior gauge control, high output, and energy efficiency. It’s ideal for industrial, packaging, and agricultural applications where quality and cost-effectiveness go hand-in-hand.

Take your extrusion operations to the next level with PROEX.

#PROEX #MonolayerExcellence #BlownFilmSolutions #RajooEngineers #FlexiblePackaging