Graphene-based Polymer Nanocomposites: The new Frontier!

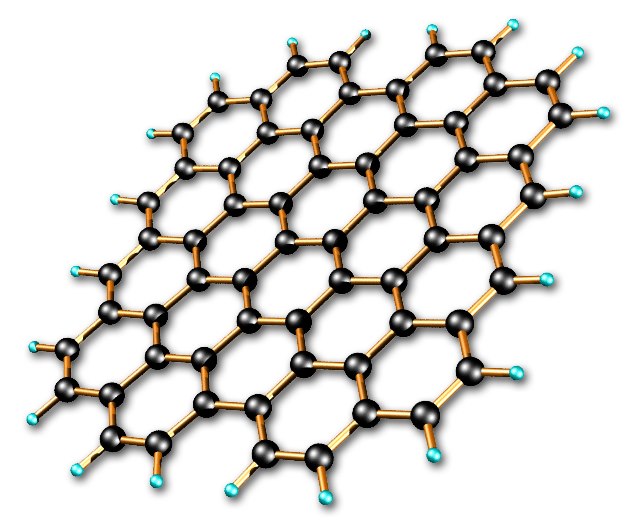

Graphite, Graphene, and Their Polymer Nanocomposites.Why such an interest in graphene? It’s all about the digital world, and the search for materials which will make integrated circuits smaller, faster and cheaper! Graphene is a semiconductor with a zero band gap and an exceptionally-high charge mobility. In fact, electron mobilities in graphene could reach values that are more than an order of magnitude higher than those encountered in a Si transistor. This opens up the tantalizing possibility that one day graphene might replace silicon as the building block of the electronic industry and revolutionize nanoelectronics.

Polymers have been combined with other polymers to form blends and copolymers, mixed with talc, calcium carbonates and clays to give filled systems and extruded and molded with fibers and other anisotropic reinforcements to yield composites and hybrid materials.

Graphene layers could be stacked, functionalized, and modified to provide numerous types of graphene-based nano-scale materials. Rolled-up graphene, known as carbon nanotubes (CNTs) also has some structural flexibility. However, the performance and cost advantages of graphene challenge CNTs in nanocomposites, coatings, sensors, and energy storage device applications.

Graphene-based Polymer Nanocomposites: The new Frontier!

Graphite, Graphene, and Their Polymer Nanocomposites.Why such an interest in graphene? It’s all about the digital world, and the search for materials which will make integrated circuits smaller, faster and cheaper! Graphene is a semiconductor with a zero band gap and an exceptionally-high charge mobility. In fact, electron mobilities in graphene could reach values that are more than an order of magnitude higher than those encountered in a Si transistor. This opens up the tantalizing possibility that one day graphene might replace silicon as the building block of the electronic industry and revolutionize nanoelectronics.

Polymers have been combined with other polymers to form blends and copolymers, mixed with talc, calcium carbonates and clays to give filled systems and extruded and molded with fibers and other anisotropic reinforcements to yield composites and hybrid materials.

Graphene layers could be stacked, functionalized, and modified to provide numerous types of graphene-based nano-scale materials. Rolled-up graphene, known as carbon nanotubes (CNTs) also has some structural flexibility. However, the performance and cost advantages of graphene challenge CNTs in nanocomposites, coatings, sensors, and energy storage device applications.

..